From our CSA Panel Shops

From simple pump controllers to complex automation projects, rely on our experts for a Custom Control Panel solution to suit your exact needs.

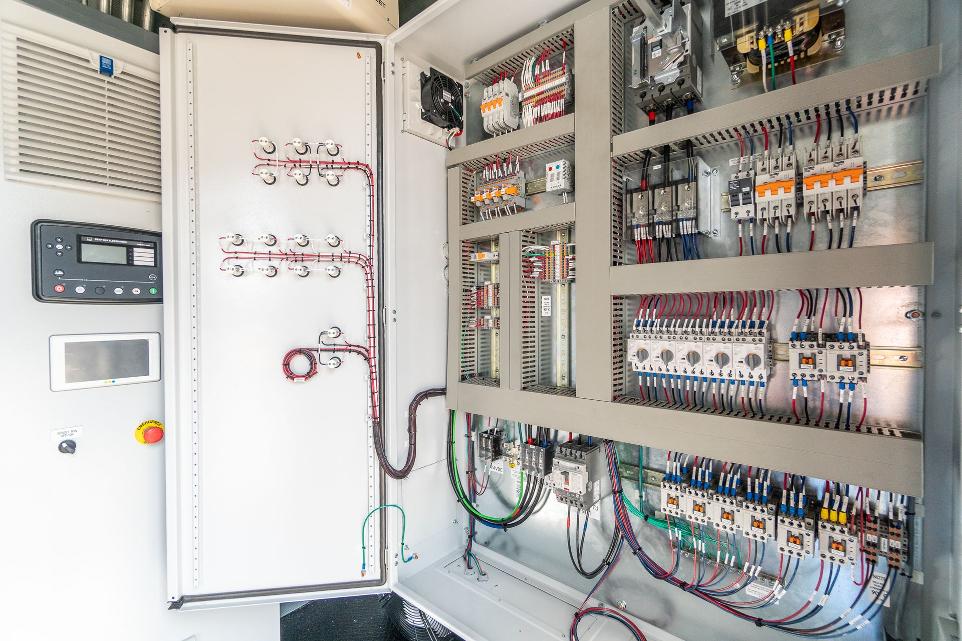

Advanced Panel Design and Fabrication

With automation trending across all sectors, it's no secret that effective and efficient control systems have a critical role to play in modern industry.

From idea to execution, our panel designers and technicians will be your trusted partners..

Microgrid Control Panels

VFD & Soft Starter Panels

PLC Panels

Operator Consoles

HMI Panels

Ground Fault Control Panels

Stainless Steel Electrical Enclosures

Commonly used in food and beverage, marine, and coastal applications, our stainless steel enclosures deliver durability, water and corrosion resistance. Get long-term reliability in protecting sensitive control systems and components.

Let our team design and build the perfect stainless steel control panel for your project.

NEMA 3R

NEMA 4

NEMA 4X

Durable

Easy to Clean

Corrosion Resistant

Panel Shop Solutions for OEMs

Partnering with the right panel shop can make all the difference for Canadian OEMs. Our team of experts can deliver tried-and-true solutions, drawing on decades of experience, and blend in the latest technology trends.

We are an extension of your electrical team, providing you with:

Private Label

Expert Design Support

Pre-built Inventory Stocking

High Volume Capacity

High Volume Pricing

Trusted by some of Canada's Top OEMs

40 YEARS of Design Expertise with Nation-Wide Support

Eleven Locations to Serve You

VANCOUVER, BC | PRINCE GEORGE, BC | EDMONTON, AB | NISKU, AB | SASKATOON, SK |

NORTH BAY, ON | MILLBANK, ON | WELLESLEY, ON | TORONTO, ON | MONTREAL, QC | MONCTON, NB

Nothing matters more than the safety of our customers and our staff, so our switchgear meet or exceed all relevant standards.

Our components come from trusted suppliers, including your preferred manufacturers when requested.

Our team of power distribution experts make each switchgear greater than the sum of its parts, dialed in to meet your exact needs.

Our efficient production teams and established supplier relationships position us to offer cost-effective solutions.

With our commitment to exceptional service, no matter when you need it, you can count on us night or day, nation-wide

40 years in business means our teams have the experience and expertise to deliver effective solutions in any industry.

...you knew exactly what we were after and you already had experience with it via other motor applications you had already written for similar purposes. I greatly appreciate your ability, technical support, and customer support throughout all the long weekend hours that we struggles to get this project done.

Matteo F. Giovanetti

Director of Technology, Electrical Engineering, DometicReady to talk about Custom Control Panels?

Frequently Asked Questions (FAQ) about Custom Control Panels in Canada

What is a custom control panel?

A custom control panel is an engineered system of electrical components like relays, switches, PLCs (Programmable Logic Controllers), and wiring, designed to control specific machinery or processes according to unique operational requirements.

What are the advantages of custom control panels over standard panels?

Custom control panels are tailored to fit specific applications, providing enhanced functionality, flexibility, and integration with existing systems compared to off-the-shelf panels.

What components are typically included in a custom control panel?

Common components include power supplies, circuit breakers, relays, contactors, VFD (Variable Frequency Drives), PLCs, HMIs (Human-Machine Interfaces), terminal blocks, and wiring.

What industries use custom control panels?

Custom control panels are used in industries such as manufacturing, water treatment, oil and gas, renewable energy, HVAC, and agriculture for precise control of machinery and processes.

What factors are considered when designing a custom control panel?

Key factors include the operational requirements, environmental conditions, available space, voltage levels, control logic, required I/O (Input/Output), and applicable industry standards or certifications.

What certifications or standards should a custom control panel meet?

Common standards include UL 508A (North America), CSA C22.2 (Canada), and IEC 61439 (international), ensuring safety, performance, and compliance with local regulations.

Can custom control panels be integrated with existing systems?

Yes, custom panels are designed to seamlessly integrate with existing equipment, communication networks, and control systems like SCADA or IoT platforms.

How long does it take to design and build a custom control panel?

The timeline varies based on complexity, but it typically ranges from a few weeks to a few months, including design, fabrication, and testing.

How are custom control panels tested before deployment?

Panels undergo thorough testing such as continuity checks, functional testing, load simulation, and environmental tests to ensure they meet design specifications and operate reliably. Reputable electrical panel builders will offer rigorous Factory Acceptance Testing (FAT) prior to delivery.

What maintenance is required for custom control panels?

Regular maintenance includes inspecting components for wear, cleaning, tightening connections, updating software (if applicable), and ensuring proper operation of control systems. Thermographic imaging to identify hot spots can also be beneficial to some control panel types.